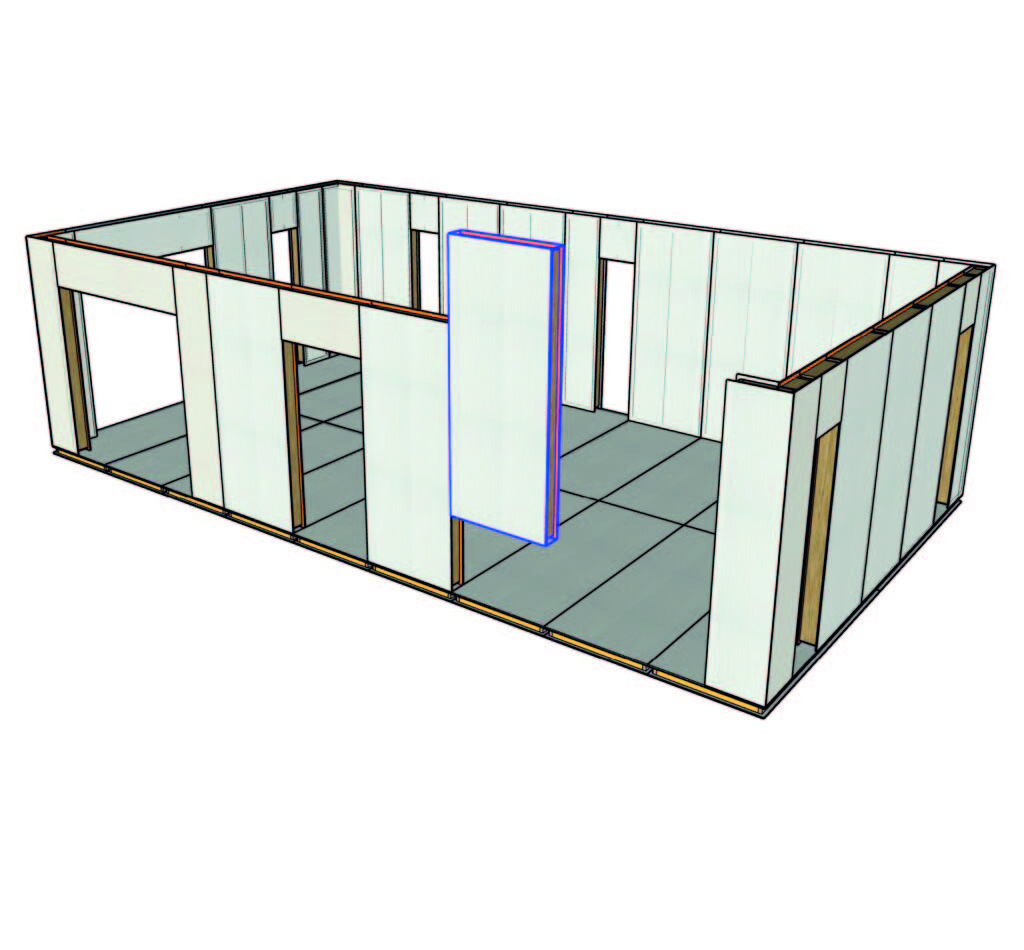

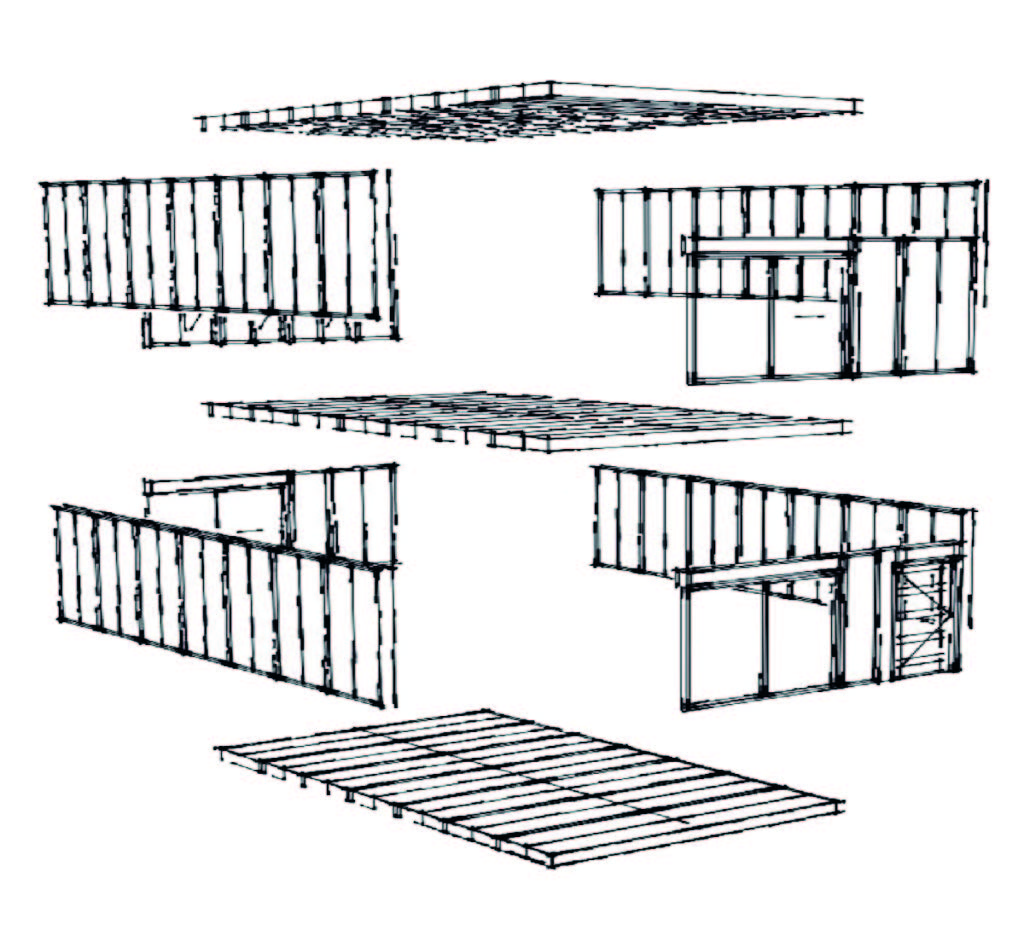

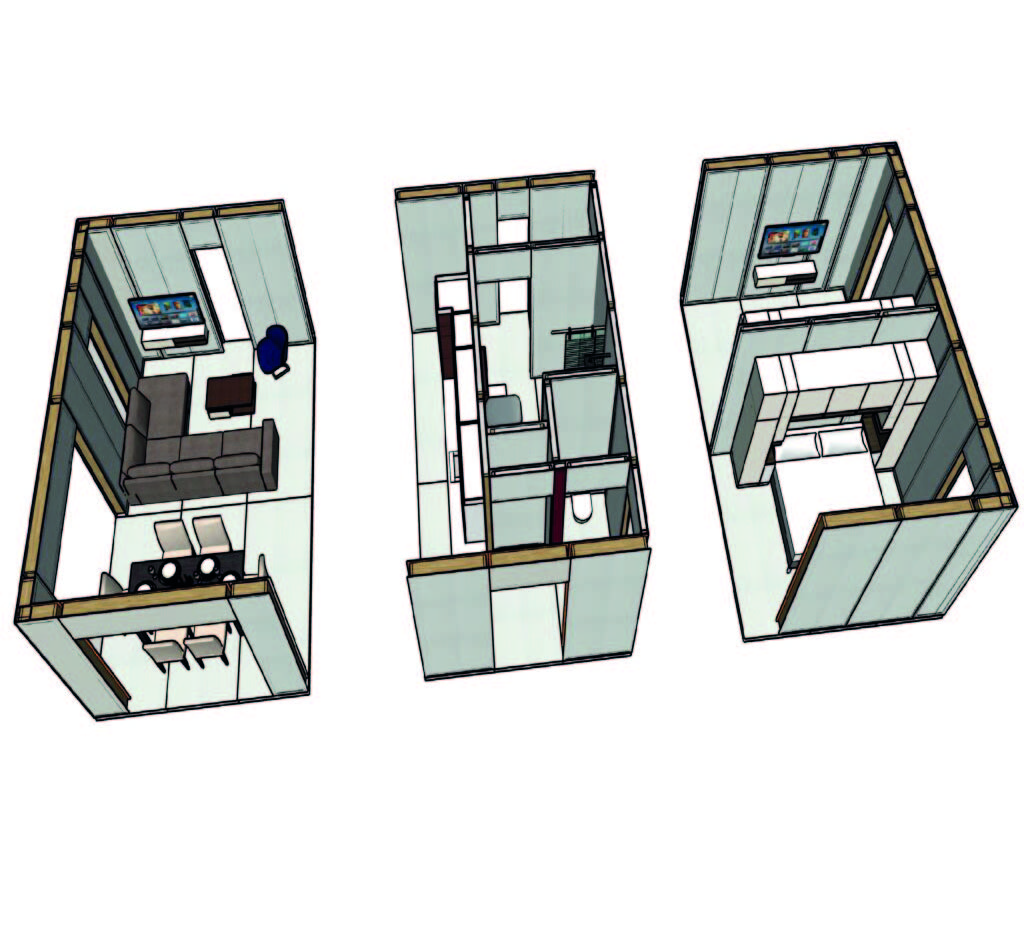

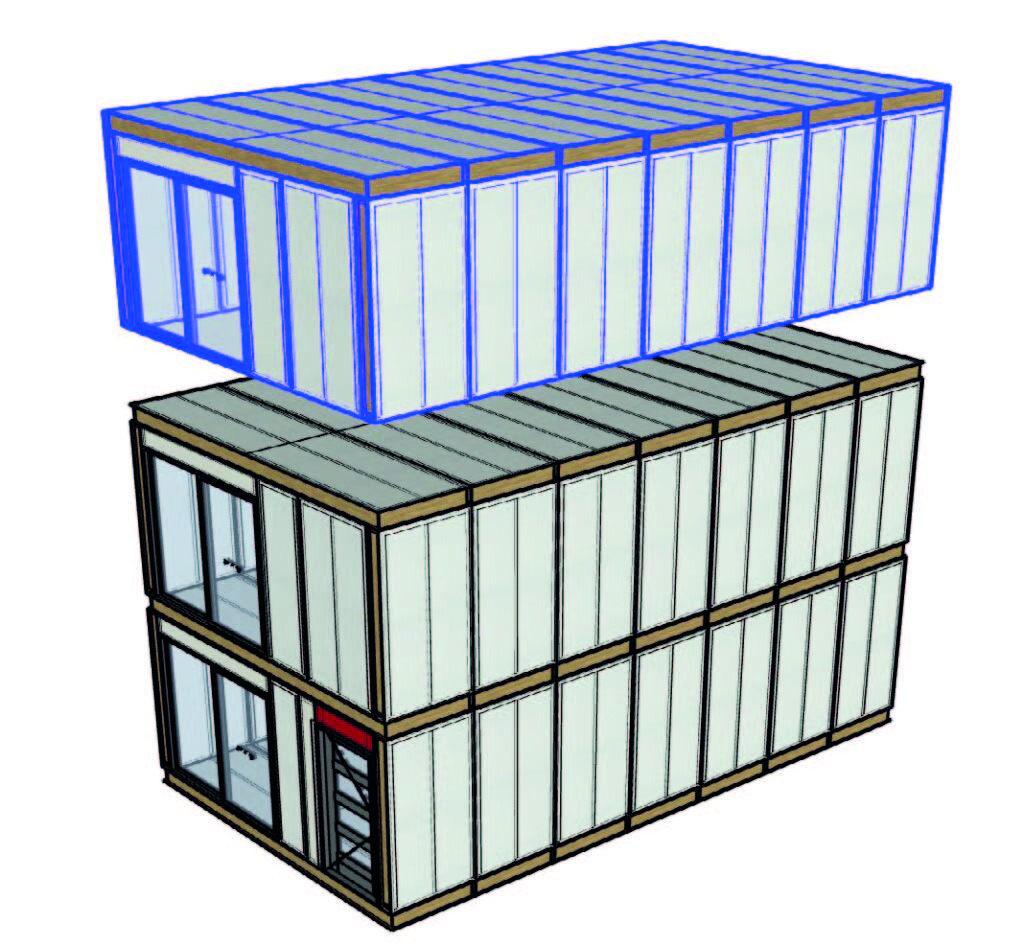

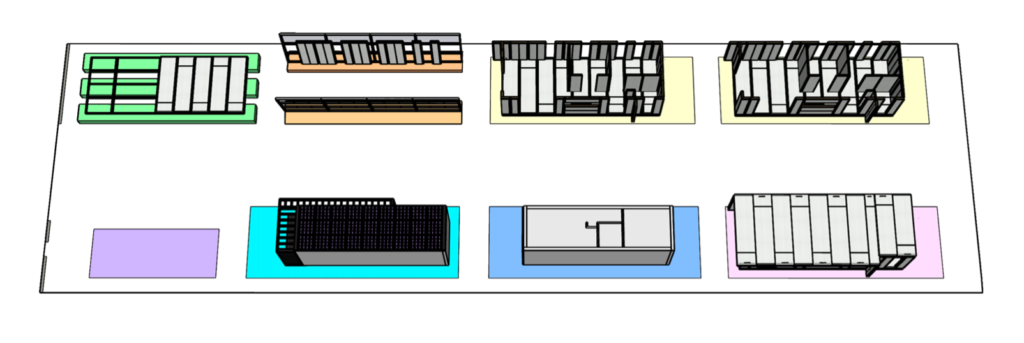

Hybrid building system

Easy to build

Building with NedPanel is straightforward and efficient, thanks to the use of standardized elements and the integration of technical systems directly into the panels. This innovative approach significantly reduces construction time and minimizes the number of professionals required for installation.

As skilled labor becomes increasingly scarce and costly, our system alleviates these challenges by simplifying the building process. The NedPanel building system not only makes construction easier and cleaner but also accelerates project timelines, allowing you to achieve your goals more quickly.

Nederlands

Nederlands Deutsch

Deutsch